Bee-Box

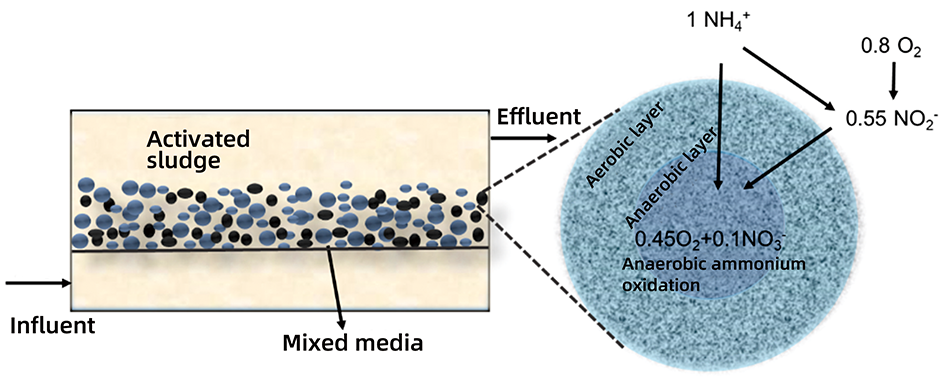

The Bee-Box is a highly effective, economical, stable, and sustainable bioreactor that makes decentralized wastewater treatment a practical solution for mid-to-large scale use cases. Standardization, modularization, and AI-powered intelligence is at the core of its design. Enabled by Forigin's proprietary IFAS-Mox (Integrated Fixed-Film Activated Sludge Mox) biotechnology, which involves precise control of microbial communities, the Bee-Box achieves a microbial immobilization rate of over 90%. This drastically improves the stability and resilience of microbial systems, creating micro-organisms resistant to low temperatures, disturbances, and starvation. Combined with the Phoenest intelligent monitoring system, the Bee-Box can operate unattended. It can also be operated digitally to adjust effluent output to various standards.

Application Scenarios

School

Hospital

Hotel

Residential Area

Industrial Park

Villages in the city

Temporary Construction Site

Military Camp

Black Stinky Water Body

River Interception

Product Advantages

Extremely stable micro-organisms highly resilient against system shocks. Forigin's micro-organisms can fully recover within 3 days even after extreme conditions (i.e. 6 months without wastewater input), does not produce any organic waste, and does not need any chemical treatment;digitally activated anti-bacterial disinfection system.

01

The effluent can meet the standards of Class I A, Class IV and Class III surface water; The equipment covers a small area, is easy to install, and can be installed on the ground or underground.

02

The product lifespan is ≥ 30 years, and the main body of the equipment is made of weathered steel + marine anti-corrosion coating.

03

Remote monitoring, unattended & automatic operations; maintenance frequency is low.

04工艺原理

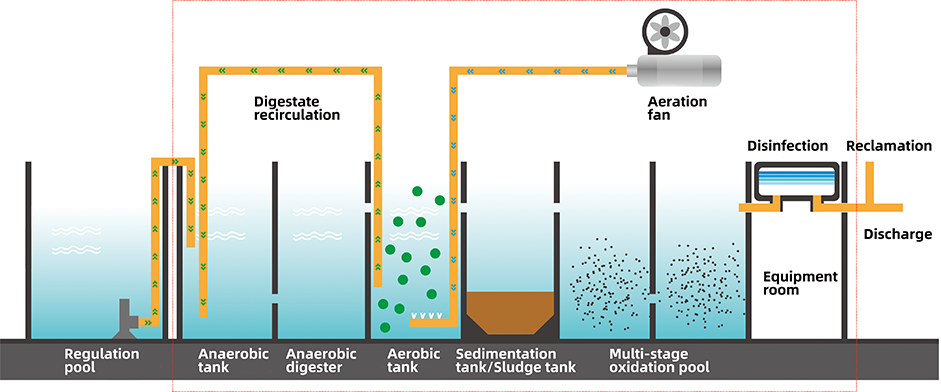

Wastewater enters the equalization tank after large suspended solids are removed by pretreatment grilles, where it is pumped into the Bee-Box. Then, the wastewater enters the anaerobic tank, anaerobic digester, and aeorobic tank for biological treatment; nitrifying liquids are air stripped back into the anaerobic tank for further denitrification. Once in the sedimentation tank, mud-water separation occurs; sludge flows back into the anaerobic tank to provide biological matter to the microbial communities, while the remaining supernatent flows into the multi-stage contact oxidation tank. The micro-environment is adjusted and carborundum microparticle biocarriers are deployed to facilitate the final stages of ammonia oxidation and phosphorus fixation. Finally, the water is sterilized by ozone before being discharged or reused.

Bee-Box Work Process Diagram

Working Mechanism Diagram of Silicon-Carbon Particle Bio-Carrier

Bee-Box Installation Diagram

Bee-Box Installation Rendering

Specifications and Models

| Model | Capacity(m³/d) | Installation Type | Size(m) | Operating Power(W) | Power Supply Mode |

|---|---|---|---|---|---|

| Bee-Box-5 | 5 | Above ground/underground | 4.0*1.2*2.2 / 3.2*1.2*2.2 | 320 | Two phase three wire 220V |

| Bee-Box-10 | 10 | Above ground/underground | 5.0*1.4*2.2 / 4.2*1.4*2.2 | 424 | Two phase three wire 220V |

| Bee-Box-20 | 20 | Above ground/underground | 5.3*1.8*2.5 / 4.5*1.8*2.5 | 440 | Three phase five wire 380V/220V |

| Bee-Box-30 | 30 | Above ground/underground | 6.8*2.0*2.5 / 6.0*2.0*2.5 | 1200 | Three phase five wire 380V/220V |

| Bee-Box-50 | 50 | Above ground/underground | 7.5*2.0*3.2 / 6.8*2.0*3.2 | 2360 | Three phase five wire 380V/220V |

| Bee-Box-100 | 100 | Above ground/underground | 11.0*2.8*3.2 / 10.0*2.8*3.2 | 3800 | Three phase five wire 380V/220V |

| Bee-Box-150 | 150 | Above ground/underground | 13.5*2.8*3.2 | 3800 | Three phase five wire 380V/220V |

| Bee-Box-200 | 200 | Above ground/underground | 15.0*3.0*3.5 | 4400 | Three phase five wire 380V/220V |

| Bee-Box-250 | 250 | Above ground/underground | 17.0*3.2*3.5 | 6160 | Three phase five wire 380V/220V |

| Note: The effluent standard is Class I B/A standard in the "Discharge Standard for Pollutants from Urban Wastewater Treatment Plants" (GB18918-2002) | |||||